A fork positioner is a hydraulic attachment that is added to the forks of a forklift. It allows the operator to adjust the distance between the forks, which can be critical when handling loads of varying sizes. The positioner enables the forks to be moved together or apart to match the width of the load being carried. This is done by using hydraulic cylinders to adjust the distance between the forks.

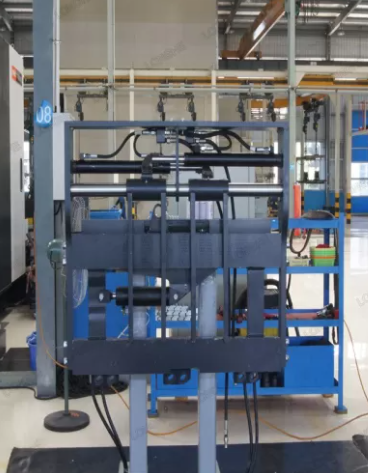

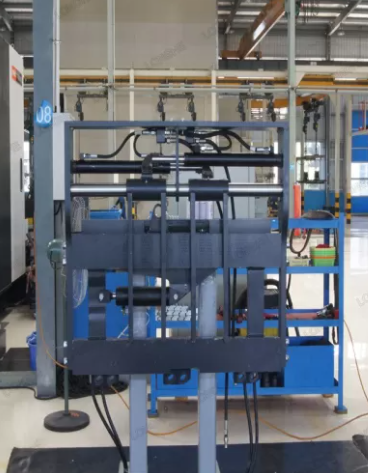

Fork Positioner Sideshifting F Series

Why Use a Fork Positioner?

Fork positioners offer several advantages over traditional forklift forks. Firstly, they improve safety by reducing the risk of damage to the load or the forklift itself. By adjusting the forks to fit the load, the operator can ensure that the load is secure and stable during transportation. This reduces the likelihood of accidents and product damage.

Secondly, fork positioners save time by eliminating the need to manually adjust the forks. This means that the operator can move from one task to another more quickly, increasing productivity and efficiency. With a fork positioner, the operator can handle loads of varying sizes without needing to stop and adjust the forks manually.

Finally, fork positioners help to reduce operator fatigue. Repetitive tasks such as adjusting the forks manually can be tiring and time-consuming. A fork positioner takes over this task, freeing up the operator to focus on other aspects of the material handling process. This reduces the likelihood of operator fatigue, which can lead to mistakes and accidents.

Types of Fork Positioners

There are several types of fork positioners available, including sideshifters, fork positioners, and rotating fork positioners.

Sideshifters are the most basic type of fork positioner. They allow the operator to move the forks sideways, which can be useful for maneuvering loads in and out of tight spaces. Sideshifters are often used in narrow aisles or areas with limited space.

Fork positioners are more advanced than sideshifters. They allow the operator to adjust the distance between the forks to match the width of the load. This is done by using hydraulic cylinders to move the forks together or apart. Fork positioners are often used in applications where loads of varying sizes need to be transported.

Rotating fork positioners are the most advanced type of fork positioner. They allow the operator to rotate the forks, which can be useful for loading and unloading pallets or containers. Rotating fork positioners are often used in applications where loads need to be turned or positioned in a specific way.

Choosing the Right Fork Positioner

Choosing the right fork positioner depends on your specific material handling needs. Consider the size and weight of the loads you need to transport, as well as the type of environment in which you will be operating. If you are working in a narrow aisle, for example, a sideshifter may be the best option. If you are transporting loads of varying sizes, a fork positioner may be more suitable.

It's also important to consider the compatibility of the fork positioner with your forklift. Not all fork positioners are compatible with all forklifts, so be sure to check the specifications before making a purchase. Or contact your manufacturer for professional guidance.