Forklifts have a variety of uses in the daily operations of your job site. However, forklift attachments can help optimize daily processes. Here are three key benefits of integrating forklift attachments into your site operations.

1. Improved performance

Forklift attachments are designed to handle a variety of responsibilities. Attachments can be easily swapped out, allowing your employees to quickly move from one task to another. This allows tasks to be completed more efficiently while eliminating downtime.

Strategically operating forklifts - such as implementing forklift attachments - helps your company move faster without the need for a variety of high-powered equipment to handle different workloads. Forklift attachments that help increase productivity include

Multiple load handlers

Multiple load handlers are designed to move more loads faster, while reducing product damage. They can carry one to six loads at a time.

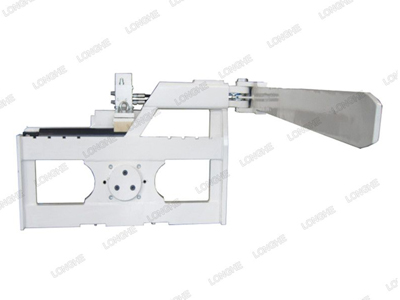

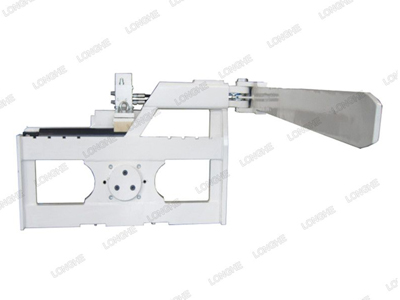

Rotators

Rotator attachments apply 360-degree rotation, allowing forklift operators to quickly flip or dump loads. What is a swivel?

Rotators allow you to rotate the forks on your truck to safely and efficiently rotate the load for dumping. We offer several types of rotator attachments: box rotators, plastic container rotators, rotators with hydraulic bin retainers, rotators with or without side shift, etc. All of these are available in 180° or 360° versions.

Rotator attachments are commonly used in industries such as agriculture, construction, food and beverage. The attachments are suitable for different types of machines. In addition to forklift rotators, we also sell rotator attachments for telescopic forklifts and skid steer loaders.

G Series Forklift Truck Rotator

2. Enhanced Safety

Workplace accidents are inevitable when operating heavy machinery, and some vehicles are more prone to accidents than others. Forklift attachments are a great tool to reduce the risk of jobsite accidents, employee injuries and load damage.

The following are some forklift attachments that support worker, employee and load safety.

Push/Pull Forklift Attachments

Push/pull allows operators to transport, receive and store loads on skids rather than pallets, thereby reducing the risk of product damage. As a result, these push/pull attachments promote efficient warehouse operations and require minimal maintenance.

Forklift Clamping Attachments

Forklift clamping attachments ensure a more efficient material handling process. Their best-selling fixture parts include.

Carton Clamps: Carton clamps allow your forklift operators to handle wider loads. They include padding, so you can take the load without damaging the item.

Paper Roll Clamps: Paper roll clamps are designed to handle paper rolls, regardless of size, weight or type of paper.

Carton Clamp

3. Reduce labor costs

An efficient warehouse requires a large number of on-site personnel. Purchasing forklift attachments and integrating them into your daily warehouse operations is a smart way to limit employee work hours. By implementing a forklift attachment, you have the opportunity to get things done with fewer employees.

This is a popular forklift attachment that helps reduce labor costs: the

Layer Picker

Layer picker attachments are used to handle single or multiple layers of individually packaged products, such as electronics, cosmetics and bottled beverages. They are commonly used in beverage warehouses and distribution facilities to reduce physical labor and increase speed and versatility.