Tobacco bale clamp is design for palletless handling operation, for tobacco leaves bale or products packed in carton, in tobacco industry with high efficiency and safety. Design of lateral sliding arm can lead for smooth clamping and sideshifting function. Its small and screwed fastening contact pad can reduce the possibilities of distortion or damaging to loads while handling, and as be worn it can be located in other place of clamp arm. Commonly used in tobacco industries.

Functions & Applications

Tobacco carton clamp can handle and stack various goods packed in cartons, especially redried-tobacco cartons, securely and efficiently without working platform. Measurements of clamp arms can be changed as requested in different working conditions. Furthermore, custom design Tobacco Carton Clamp for special working condition in cigarettes factory is available.

Features

● Proven durable T-beam arm and aluminum alloy frame construction

● Superior arm-slide bearing for extended service life

● Small rubber pads design, economically

● Regenerative hydraulic valuing for optimal arm speed

● Excellent driver visibility options

● Custom opening ranges

● Custom arm size

● Various mounting classes available 100%

● Load backrests

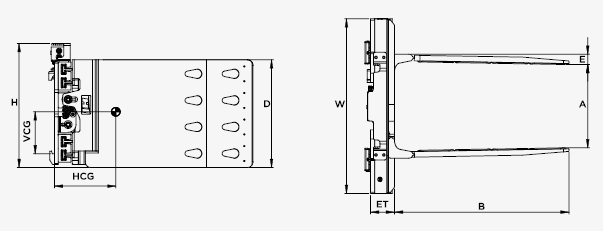

| Capacity@ Load Center | Model | Mounting Class | Opening Range | Arm Height | Arm Length | Arm Thickness | Frame Width | Overall Height | Vertical Center of Gravity | Weight | Effective Thickness | Horizontal Center of Gravity |

| (kg@mm) | A(mm) | D(mm) | B(mm) | E(mm) | W(mm) | H(mm) | VCG(mm) | (kg) | ET(mm) | HCG(mm) | ||

| 1400@500 | YYC14D-B001 | II | 460-1620 | 580 | 940 | 55 | 940 | 667 | 223 | 433 | 128 | 326 |

| 1400@500 | YYC14D-B002 | II | 460-1620 | 580 | 1140 | 55 | 940 | 667 | 222 | 472 | 128 | 410 |

| 1900@500 | YYC19D-B001 | II | 500-1790 | 580 | 1140 | 55 | 1040 | 667 | 220 | 480 | 128 | 401 |

| 1900@500 | YYC19D-B002/C002 | II/III | 500-1790 | 580 | 1340 | 60 | 1040 | 667/706 | 220 | 556 | 130 | 501 |

Recommend Hydraulic Flow: 40L/min –120L/min

Pressure: 160 Bar

Note

1. Please contact FLT manufacture for the residual capacity of attachment

2. 2 additional hydraulic circuits

3. Opening range refers to distance between arm tips

4. Dimension E refers to operation space required for arm

5. Without sideshifting can be available

* Further technical details are available upon request