Rotating bale clamp applies efficiently and economically handling stacking or rotating nearly any type of baled products including cotton wool, synthetic, textile bales, corrugated, newsprint, rag, hay metal and other scrap bales in palletless operation condition. Commonly equipped in industries as mill, material recycling, railway transportation, logistic warehouse, port, textile and related.

Functions &Applications

Bale clamp efficiently and economically handle nearly any type of baled products including cotton, wool, synthetic, textile bales, corrugated, newsprint, rag, hay, metal and other scrap bales. High efficiency and economy to handle in without work platform condition.

Features

● Proven durable T-beam sliding pair, high intensity and long service life

● High strengh T-beam alloy steel material meets all kind of operation requirements

● Superior arm-slide bearing for extended service life

● Inner arm with fillet design, increased the coefficient of friction Regenerative hydraulic valving for optimal arm speed

Options

● Custom opening ranges

● Custom arm sizes

● Custom arm ribbing

● Various mounting classes available.

● Load backrests

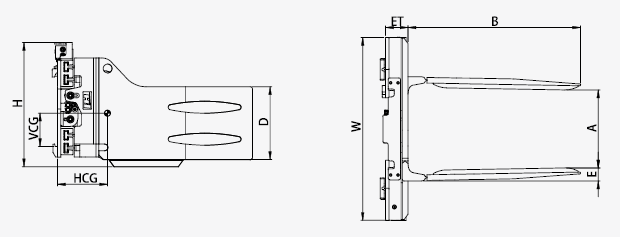

| Capacity@ Load Center | Model | Mounting Class | Opening Range | Arm Height | Arm Length | Frame Width | Arm Thickness | Overall Height | Vertical Center of Gravity | Weight | Effective Thickness | Horizontal Center of Gravity |

| (kg@mm) | A(mm) | D(mm) | B(mm) | W(mm) | E(mm) | H(mm) | VCG(mm) | (kg) | ET(mm) | HCG(mm) | ||

| 1900@500 | RBX19D-C004 | III | 440-1730 | 415 | 982 | 1040 | 70 | 775 | 335 | 620 | 283 | 300 |

| 2700@500 | RBX27D-C001 | III | 560-1910 | 460 | 1180 | 1050 | 80 | 775 | 335 | 790 | 298 | 432 |

Recommend Hydraulic Flow: 40L/min –120L/min

Pressure: 160 Bar

Note

1. Please contact FLT manufacture for the residual capacity of attachment

2. 2 additional hydraulic circuits

3. Opening range refers to distance between arm tips

4. Dimension E refers to operation space required for arm

* Further technical details are available upon request