Mainly applied in handling, stacking, loading or unloading kinds paper rolls at site. Pivot arm design with 360° rotating function enables the paper roll clamp to handle rolls that is both placed vertically or horizontally. Found in paper mills, newspaper printing, concret or steel pipe, logictics warehouse, converters and any industries that handles paper rolls or rolls.

Functions & Applications

Designed for mills, warehouses, printers, newspaper publishers and converters.

Features

● Rational designed, compact structure, excellent driver visibility, easy operating, improve work efficiency

● Thin arm profile and smooth arm contour eases roll breakout

● Contact pads with integral casting structure, abrasion resistance, long service life. Contact pads surface reasonable, provide the best clamping friction

● Continuous 360° rotation, any angle position of lock function, revolving positing 90° or 180°

● Hydraulic retention of cylinder valves is to ensure reliable clamping of long distance transportation.

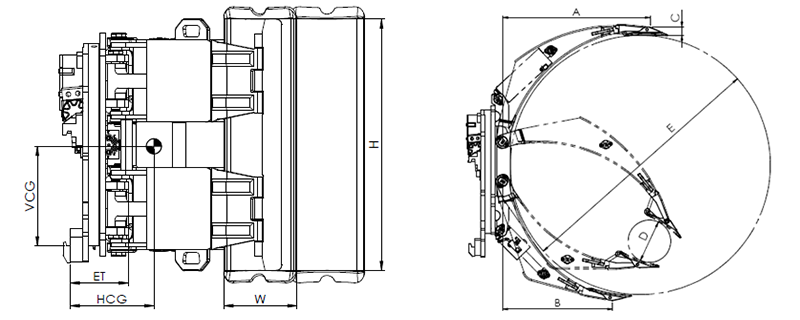

| Capacity | Roll Range | Type | Mounting Class | Long Arm Length | Short Arm Length | Long Arm Thickness | Vertical Center of Gravity | Weight | Effective Thickness | Horizontal Center of Gravity | |

| (mm) | A(mm) | B(mm) | C(mm) | VCG(mm) | (kg) | ET(mm) | HCG(mm) | ||||

| 2200/700 | ZJJ25G-B022/C022 | 200-1400 | A | II/III | 1017 | 681 | 51 | 343 | 640 | 205/256 | 362 |

| 2000/750 | ZJJ25G-B005/C005 | 450-1500 | B | II/III | 1058 | 711 | 51 | 357 | 660 | 205/255 | 359 |

| 2000/800 | ZJJ25G-B008/C008 | 200-1600 | A | II/III | 1118 | 840 | 51 | 355 | 670 | 205/255 | 360 |

Recommend Hydraulic Flow: 40L/min –120L/min

Pressure: 160 Bar

Rotating Speed: 7.5r/min@40L/min 5.2r/min@40L/min 3.2r/min@40L/min

Rotating Torgue: 4200N´m@160Bar 9000N´m@160Bar 11000N´m@160Bar

Note

1. Please contact FLT manufacture for the residual capacity of attachment

2. 2 additional hydraulic circuits required

3. Type“A”fixed short arms, Type“B”adjustable short arms, Type“C” contact pad splited

* Further technical details are available upon request